Our Infrastructure at a Glance

Sanraj Polyprinters operates with two state-of-the-art facilities spanning 38,000 square meters in Rajkot, Gujarat, designed to handle every stage of flexible packaging production. With cutting-edge machinery, in-house film extrusion, and robust quality systems, our plants combine efficiency, innovation, and sustainability to serve 150+ clients across industries

Facilities

- 2 State-of-the-Art Facilities – covering a combined area of 40,000 square meters.

- In-House Ink Kitchen – ensuring precise colour formulation and consistency.

- Automated Solvent System – for safety, accuracy, and operational efficiency.

- Temperature-Controlled Positive Pressure Systems – maintaining safe, controlled environments for both processes and people.

- In-House Performance & Testing QC Lab – ensuring every roll and pouch meets global quality standards.

- Certifications – facilities certified with BRCGS Packaging Materials, ISO 9001: Quality Management, ISO 14001: Environmental Management, and (other standards like HACCP, if applicable).

Machinery

- 6 High-Speed Rotogravure Printing Presses – delivering precision and speed.

- 3 Extrusion Coating Machines – for advanced barrier packaging.

- 1 Heavy-Duty Extrusion Coating Machine – dedicated for bulk and heavy-duty packaging applications.

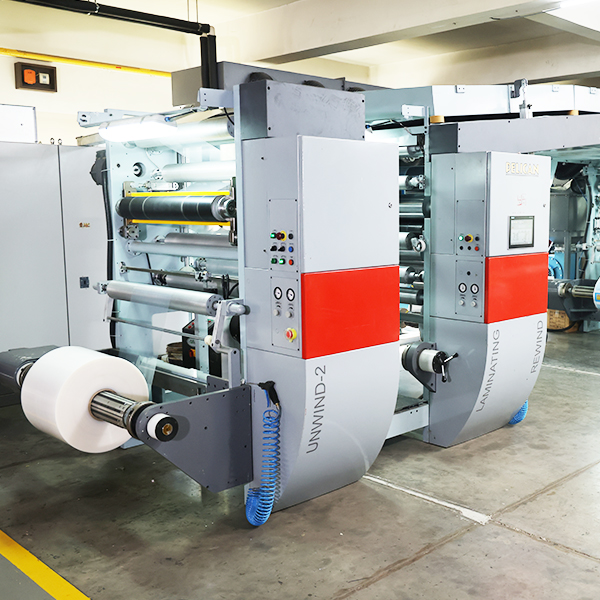

- 5 Solvent-Less Lamination Machines – eco-friendly lamination with reduced solvent usage.

- 1 Solvent-Based Laminator – for specialized structures.

- 7 Slitters – ensuring precise cutting and roll finishing.

- 1 Laser Scoring Machine – enabling easy-open packaging solutions.

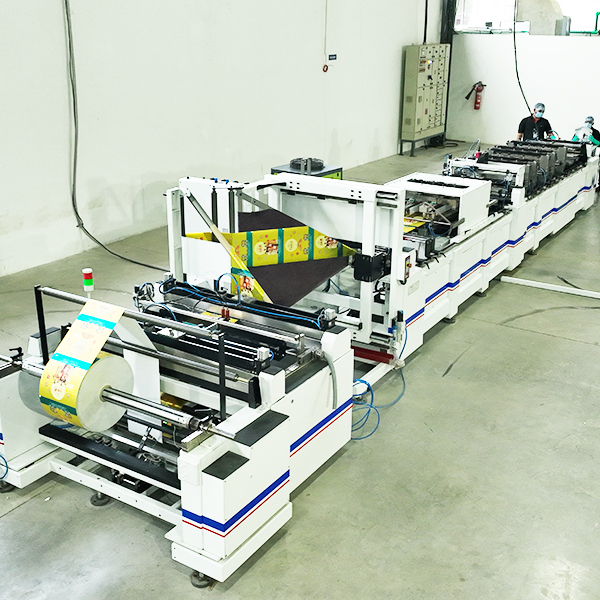

- 8 Pouching Units – versatile formats for retail-ready and bulk applications.

- 1 Blown Film Extrusion – maintain quality and consistent supply.

Technology & Sustainability

- Solar-Powered Operations – rooftop solar installations actively reducing carbon footprints year after year.

- Waste Reduction Practices – efficiency-driven processes that minimize environmental impact.

- Green Environment & Premises – promoting eco-conscious workspaces and cleaner operations.

- Striving Toward Recyclable Structures – advancing packaging innovation with recyclability at its core.